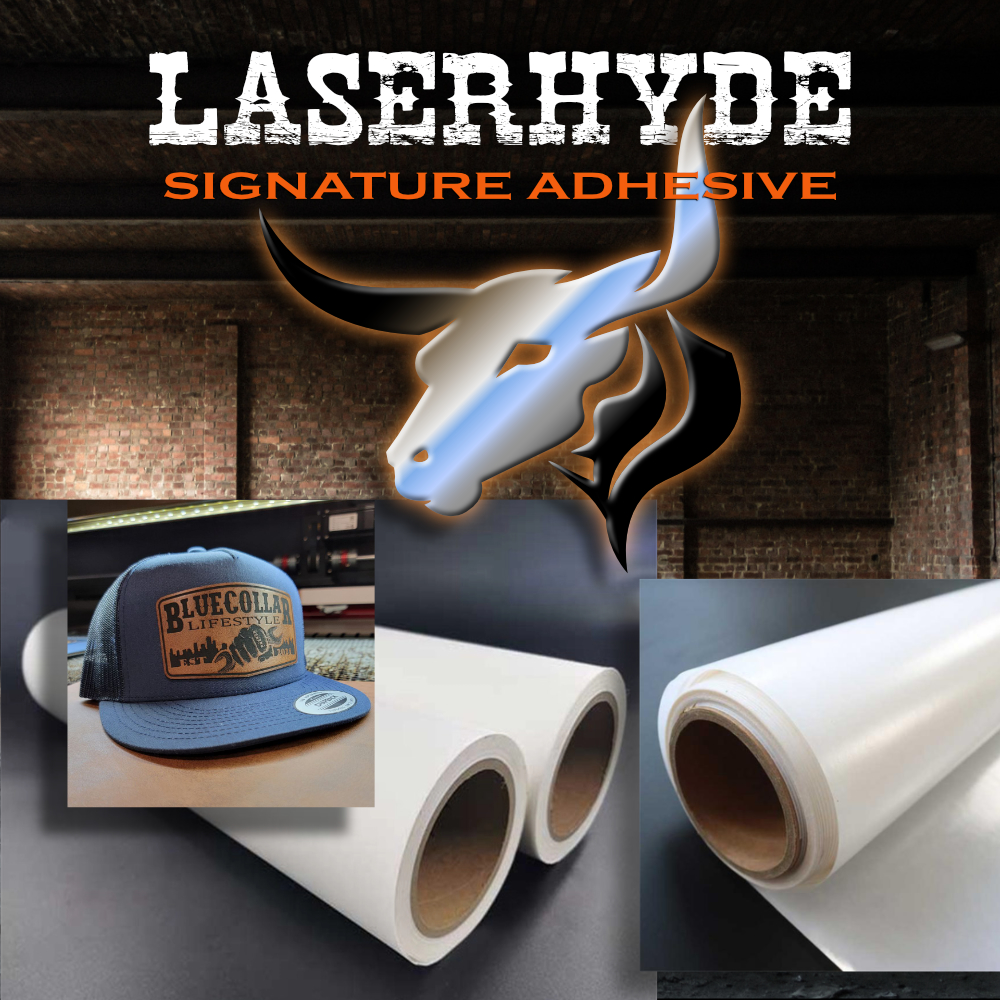

Laserhyde Thermal Adhesive Film – Low Temperature

Laserhyde Thermal Adhesive Film, is our leading industrial strength thermoplastic poly adhesive which creates amazing permanent bonds to various substrates, while achieving water resistance, up to 130F. and lower heat application bonding temperatures. When using Laserhyde thermal het press film adhesives, you can feel confident and assured knowing our stronger thicker 6 mil adhesive will get the job done, and create a durable bond, that will last with amazing flexability, created for the industry of hat patch decorating and fabric bonding choose Laserhyde and experiance why we are the best choice!

Laserhyde Adhesive Features

- Competitively priced as low as 2.6 cents per square inch (Thicker material and better features when compared to other top companies)

- Thermoplastic 2 sided hot melt film heat press adhesive

- Our adhesive and paper backing offers smooth clean laser cutting

- Thermal heat activated heat press adhesive sheet

- 6 mil thickness

- Water resistant up to 55°C (130°F)

- Low temperature adhesive film for leather and hat patches (See instructions on page below)

- Excellent adhesion to most soft and hard textile products

- Dry Clean friendly

- Dry to touch application (non tack formula)

- Cold peel the film after 1st application, or leave the film on for easy clean laser cutting.

- Laserhyde™ Adhesive is OEKO-TEX Standard 100 Certified

- Laser-Safe product

Laserhyde Product Applications

- Leather patch adhesive

- Leatherette engravable sheet panels

- Apparel projects

- Leatherette patches

- Fabric materials

- Cosplay projects

- Wood/Veneer panels

- Acrylic Sheet panels

- Acrylic patches

- Embroidery patches

- Hat patch adhesive

- Velcro Hook and Loop Fabric panels (not the smooth backed versions)

- And more

DONT FORGET TO CHECK OUT OUR LASERHYDE™ LEATHERETTE ENGRAVABLE SHEETS

IMPORTANT POLICY INFO:

Reviews

There are no reviews yet