Laserhyde Deluxe™ Cognac Latigo Leatherette Sheet

RATED #1 BEST LEATHERETTE FOR HAT PATCHES

Laserhyde Deluxe™ Cognac Latigo Leatherette is a top-quality smooth satin finish stressed leather simulated material designed for laser engraving. Our leatherette sheets with adhesive features our strong industry-leading Laserhyde thermoplastic low temp poly adhesive, perfect for heat-sensitive materials like polyester fabrics and acrylic panels. Laserhyde Deluxe leatherette was engineered for water-resistance, with reinforced layers for added strength while remaining extremely flexible. With Laserhyde Deluxe Leatherette, your hat patches will be thicker, bolder, and stronger, making it the best choice for laser engraving businesses and custom hat decorators.

LASERHYDE DELUXE LEATHERETTE FEATURES:

- Laserhyde Deluxe™ Cognac Latigo Leatherette Leatherette

- UV Printable leatherette

- Actual sheet dimensions 11.75 x 17.70 inches (Die Cut)

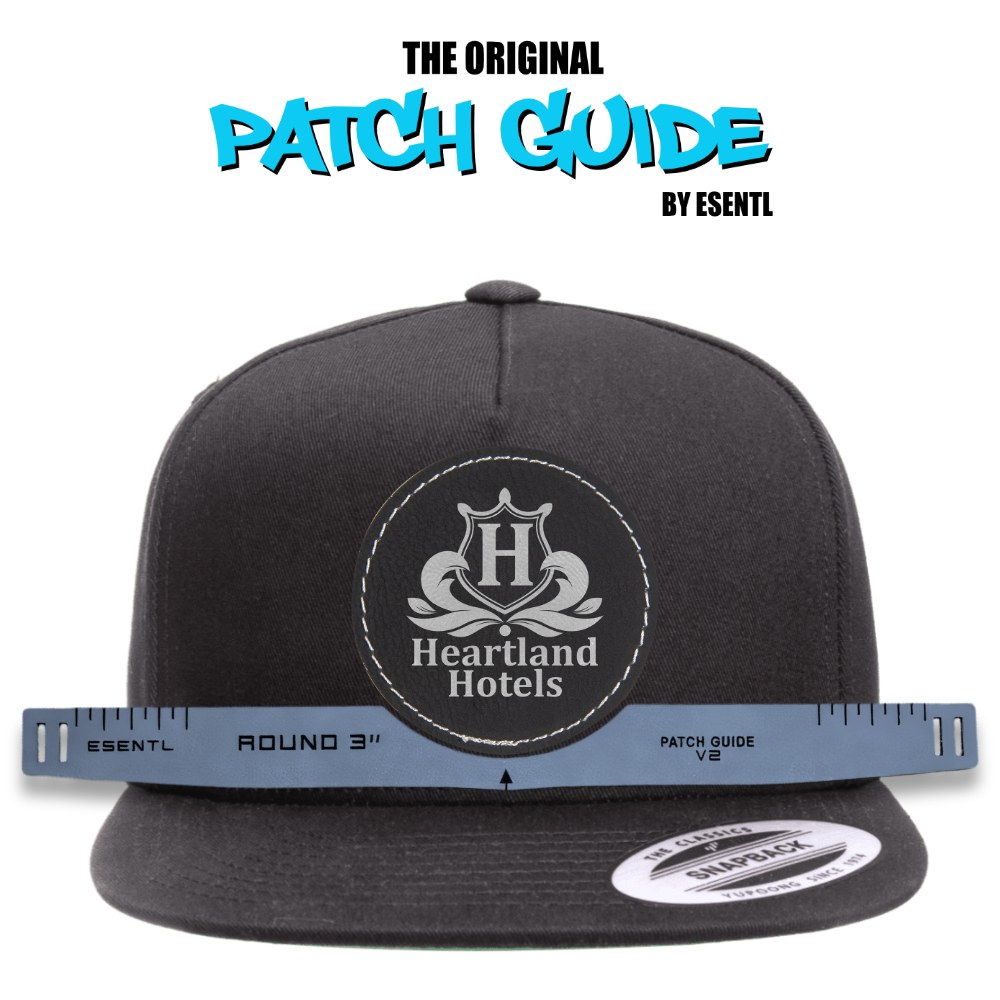

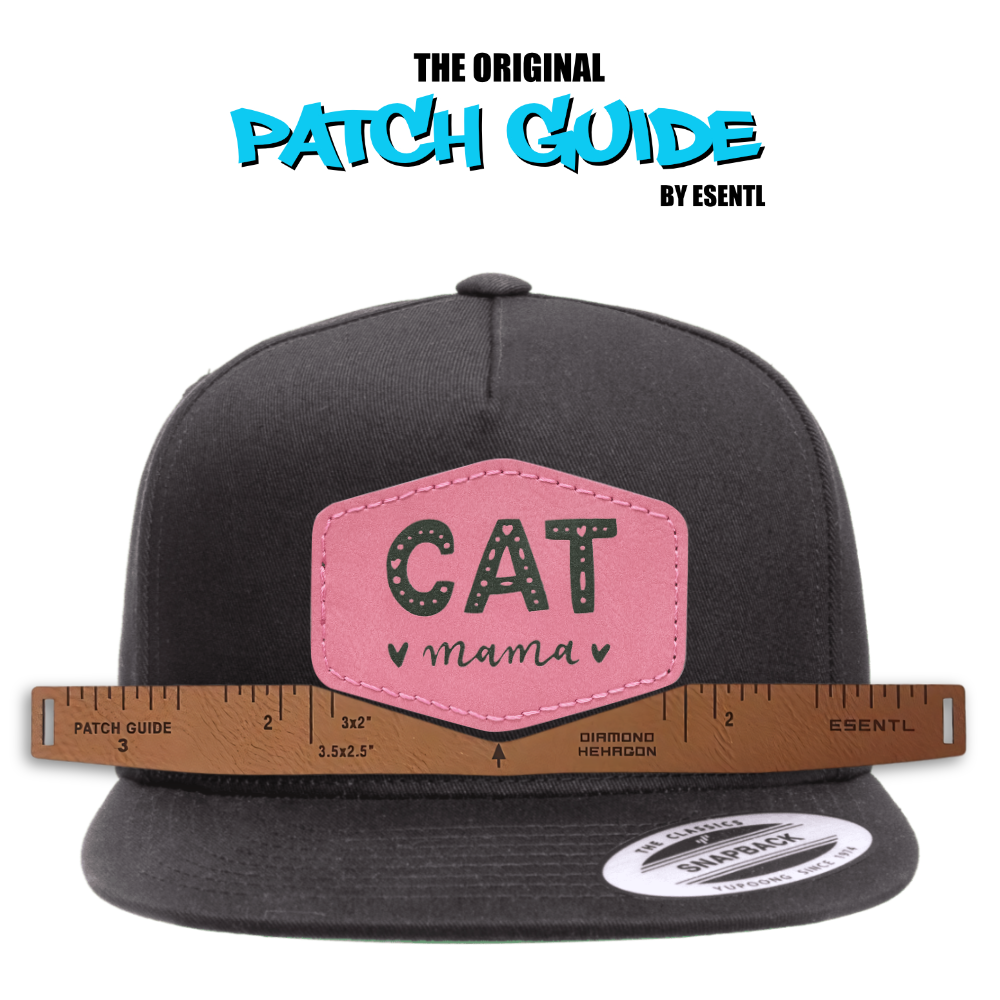

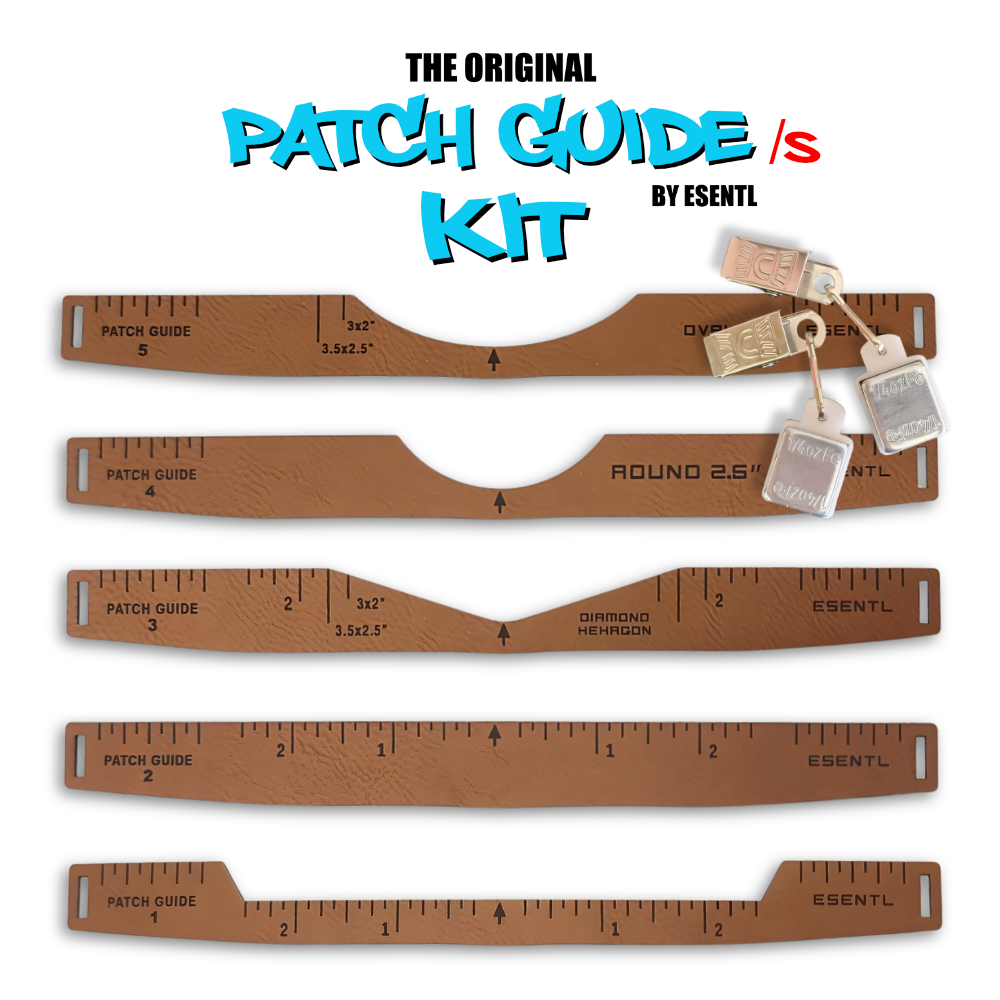

- Leatherette is the perfect hat patch material for creating thicker premium simulated leather style patches

- Main Color: Cognac

- Engraving Color: Black

- Laserhyde laser engravable leatherette sheet is a laser safe product

- Not prone to fading from sunlight

- Does not need to be sealed

- Thicker leatherette sheet – 1.85-2.15mm thickness range with and without adhesive that simulates a 5-6 ounce leather

- Easy to clean product – (Recommendations: LA Awesome Cleaner with 50/50 water dilution)

- Laserhyde Deluxe Leatherette is a water proof material

- Bonded using our Laserhyde water resistant and washable thermoplastic film adhesive (heat press friendly) – LEARN MORE

- Animal cruelty free vegan faux leatherette material

- Cost affective material when compared to to any other real leather product

*ADD SOME POP TO YOUR LEATHERETTE WITH OUR LINEUP OF FULL-COLOR SUPREME DTF TRANSFERS – PICK YOUR STYLE! HERE

ABOUT LASERHYDE™ DELUXE ADHESIVE

LaserHyde was created to be a water-resistant adhesive, with a two-sided thermoplastic film that bonds extremely well to soft and hard textiles. It’s safe for dry cleaning and can handle wash temperatures up to 60℃. With its low melting point, it prevents damage to sensitive performance fabrics, and acrylic or plastic panel sheets. LaserHyde works on a variety of materials, including apparel clothing, beanies, footwear, leather, embroidery, twill, wood, veneer, plastics, acrylics and more, with bonding temperatures varying by material. It was thoroughly tested and engineered to be the perfect adhesive for hat patches.

OEKO-TEX Standard 100 Certified Safe Adhesive

SOCIAL MEDIA

“Want the latest videos and tutorials for patch making and laser engraving? Follow me on YouTube” – CLICK HERE

“Want the latest product drops, patch previews, and community creations? Join our private Hat Patch Creators Facebook group!” CLICK HERE

Reviews

There are no reviews yet