LEATHERETTE AND ADHESIVE SUPPLY COMPANY

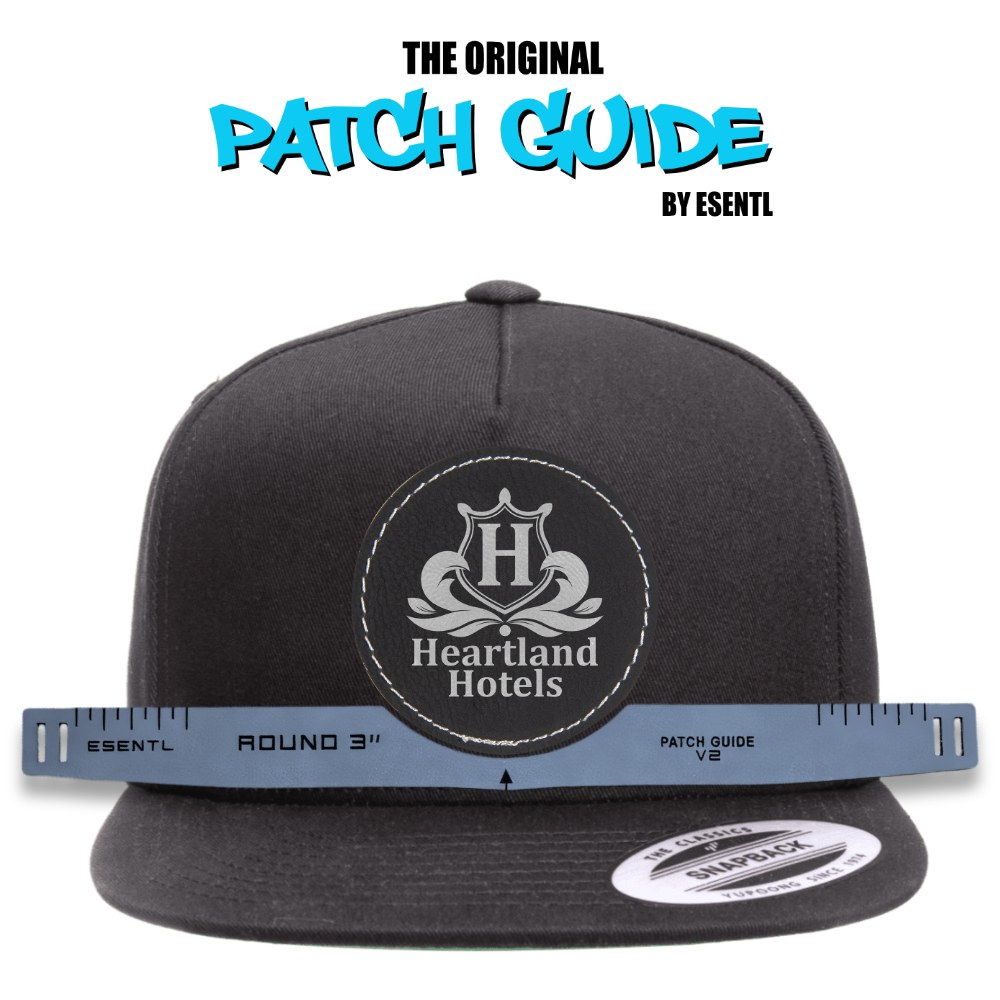

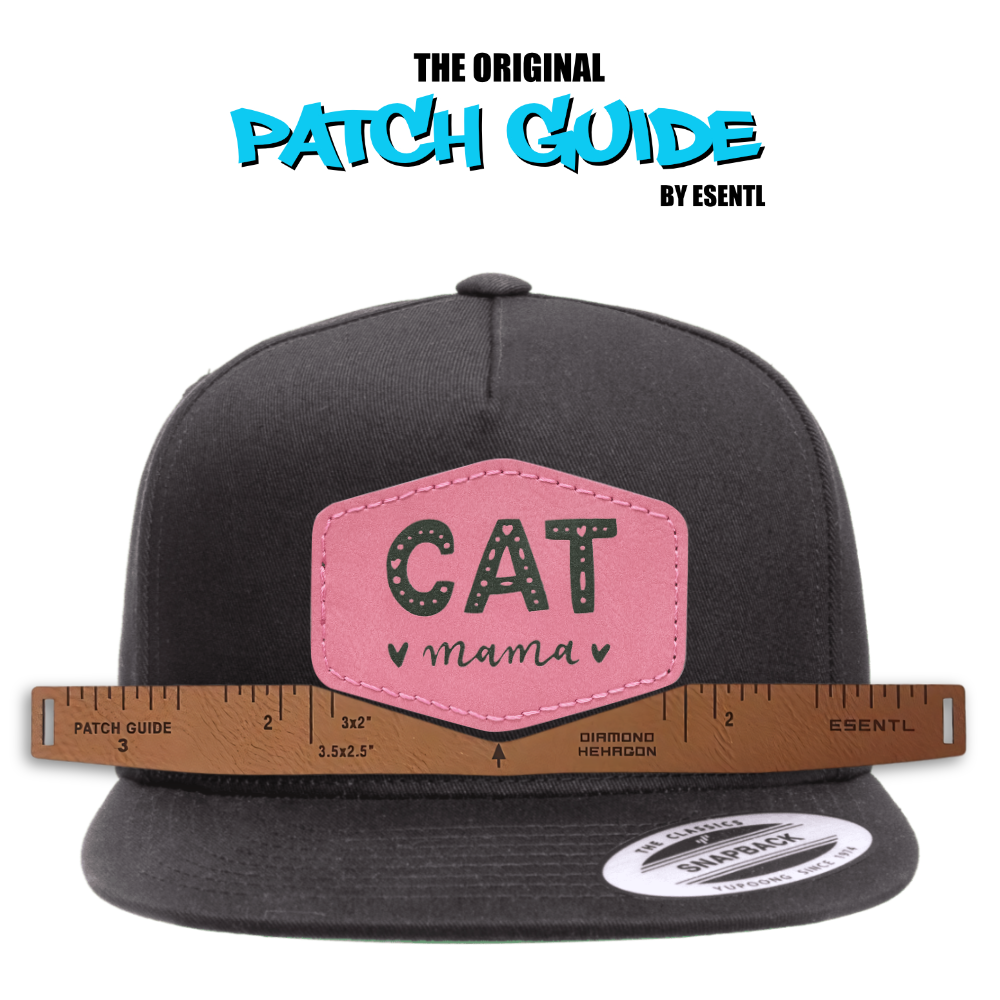

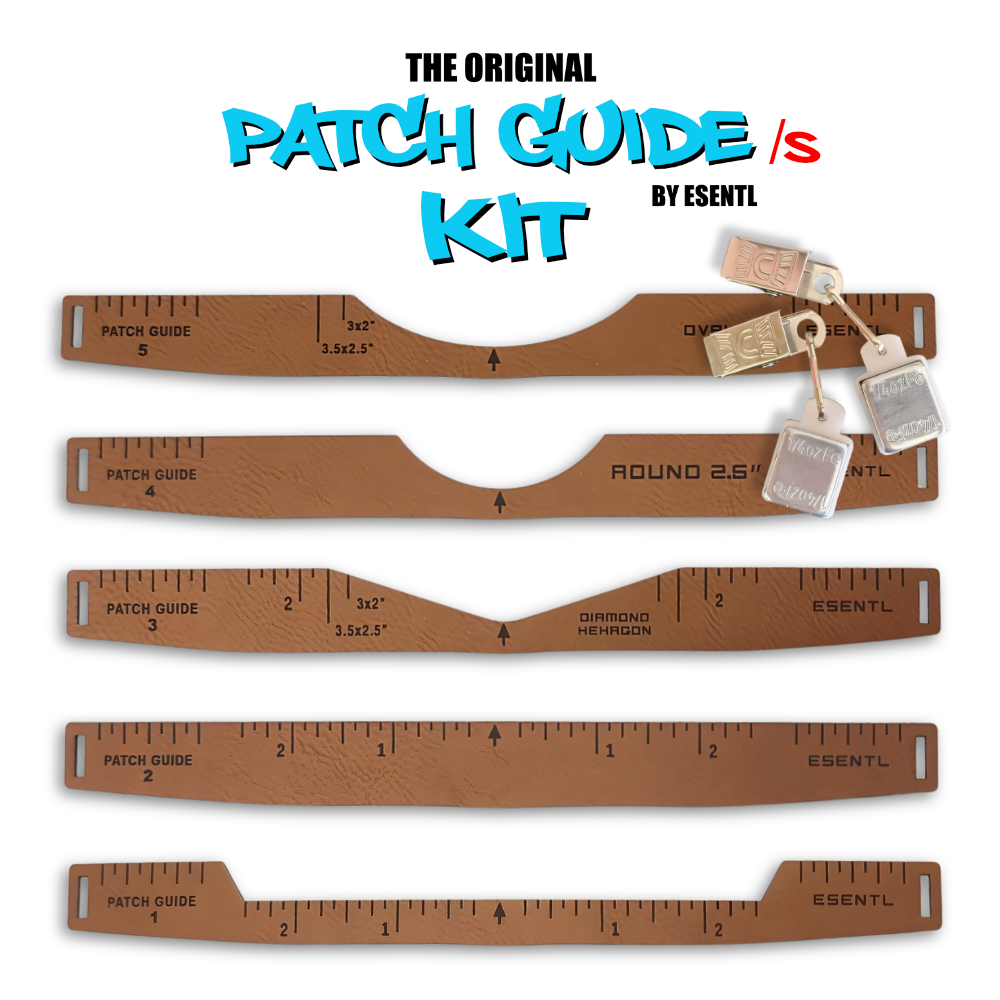

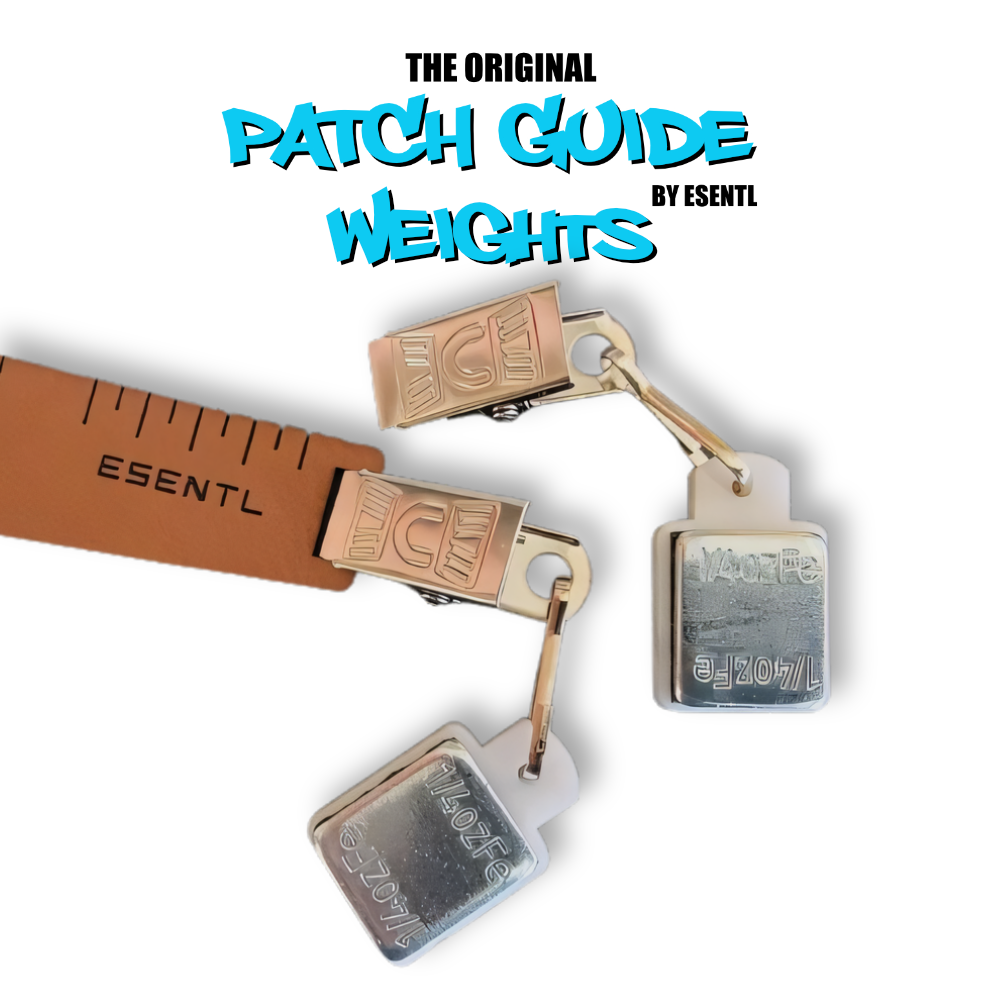

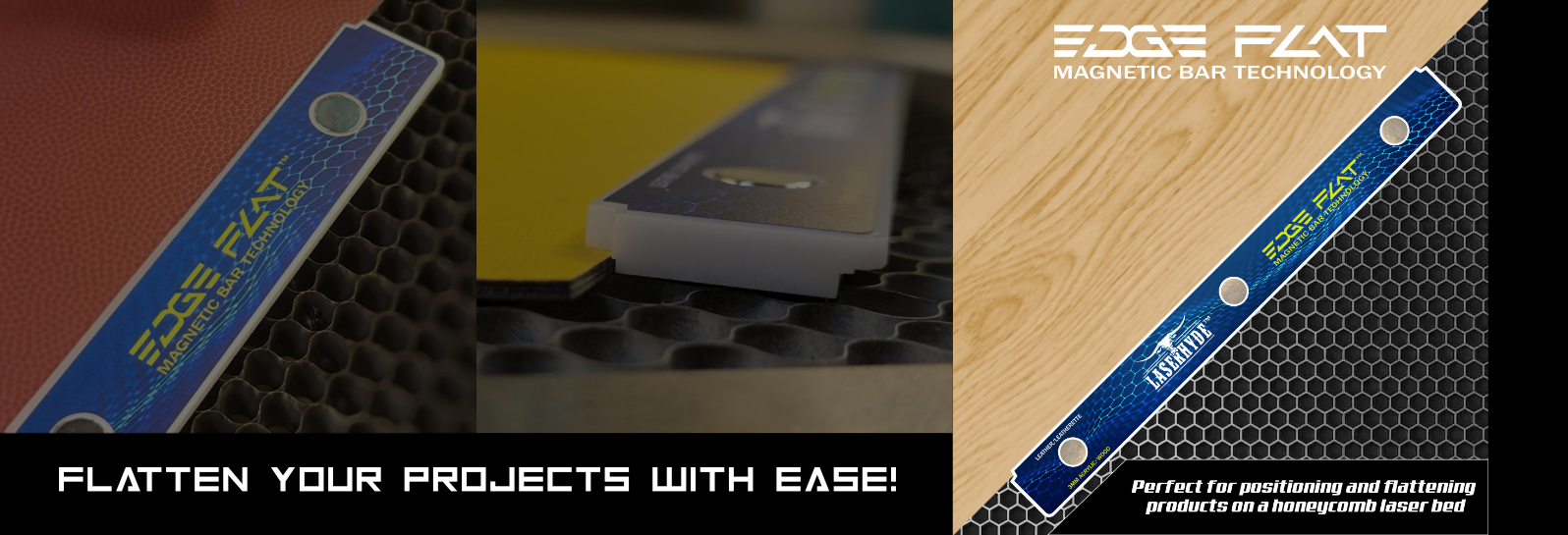

HAT PATCH ALIGNMENT GUIDES KIT

PERFECT PATCH ALIGNMENT EVERY TIME

REGISTER AND GET $5 IN LASERHYDE POINTS

EARN USUABLE POINTS FOR EVERY DOLLAR SPENT

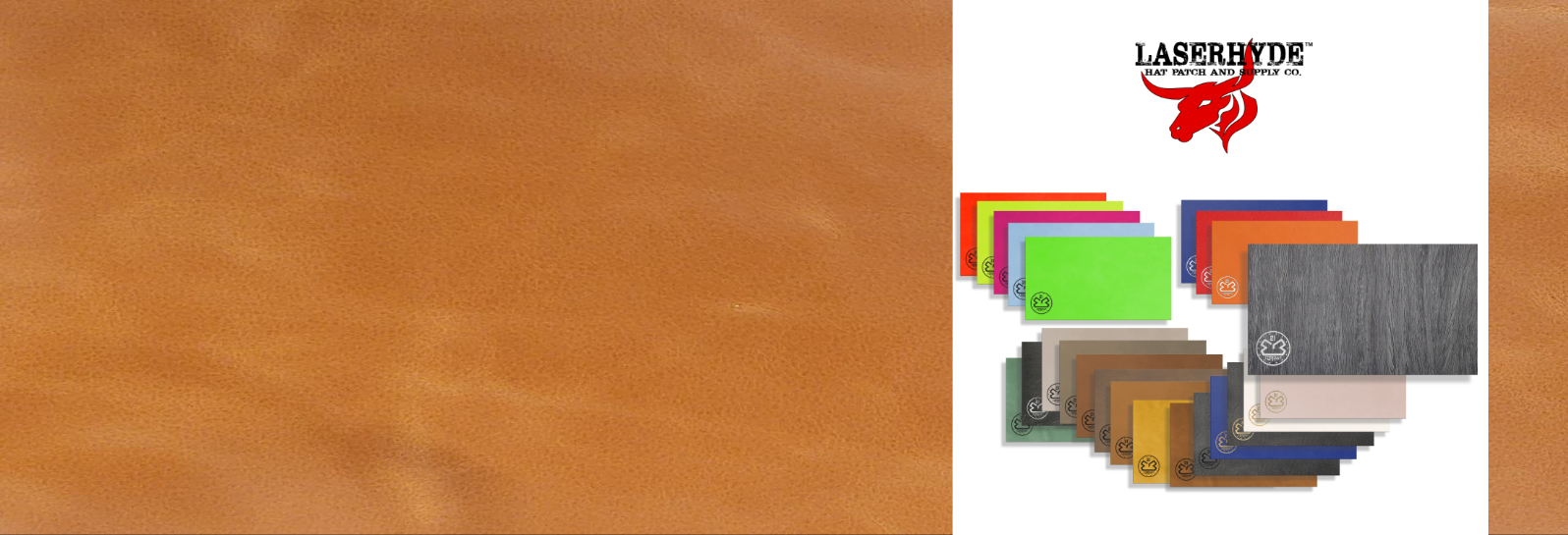

10 NEW LEATHERETTE COLORS ADDED IN NOVEMEBER

CHOOSE THE INDUSTRY BEST ... CHOOSE LASERHYDE DELUXE!

LASERHYDE DELUXE LEATHERETTE SHEETS

HAT PATCH TOOL PRODUCTS

LASERHYDE DELUXE HAT PATCHES

LASERHYDE Deluxe CustomIZED Hat Patches

Laserhyde Deluxe Blank Hat Patches

CUSTOMIZABLE PRE-STITCHED PATCHES

LASERHYDE Custom LOGO Rivet Hat Tags

DIGITAL HAT PATCH GRAPHIC SETS

NEW PRODUCT AND ADDING MORE WEEKLY!

SUPPORT GROUPS

jOIN OUR OFFICAL FACEBOOK LASERHYDE SUPPORT AND PATCH MAKERS GROUP FOR THE LATEST NEWS AND UPDATES!

SEE OUR FACEBOOK GROUP PINNED POST FOR MORE DETAILS

... EXPERIANCE THE LASERHYDE DIFFERANCE ...

Welcome to LaserHyde™ | Engravable Leatherette Supply Company

Are you looking for a Quality Leatherette Supply Company? At Laserhyde, we have become a trusted source for our amazing top tier quality Engravable Leatherette, and Leather Hat Patch Adhesive. I have poured extensive time, research. and development into crafting an amazing product for laser engraving professionals and hat decorating enthusiasts. Our Laserhyde Deluxe™ thick leatherette sheets and low temperature thermal-activated film adhesives are setting a new leading standard within the hat decorating and print industry.

Specifically engineered for the hat patch decoration market and laser engraving community, Laserhyde delivers pro-level quality, reliability, and performance — all with competitive pricing in mind. Compared to leading brands, our products offers affordability, true superior quality, stronger adhesion, precision laser cutting, awesome color options and an amazing finish every time.

Whether you’re designing custom leather products, leatherette patches, personalized gifts, premium branded merchandise, or custom hats, Laserhyde products will give you the confidence to create with consistency and excellence.

Experience the LaserHyde™ difference — where craftsmanship meets innovation.

Need more Info? email us at info@laserhyde.com

Join our Official Facebook Patch makers Group and check us out on Social Media